Technology expert presents prototype for leading automotive manufacturers

New battery solutions and thermal management modules for electric mobility are more in demand than ever. At the Battery Show Europe, the largest trade fair for battery technology, Handtmann Systemtechnik GmbH & Co. KG will showcase its extensive portfolio for sustainable mobility. The trade fair stand will focus on the new hybrid battery that Handtmann has developed for a leading automotive manufacturer, a modular high-voltage battery system and the ITS, a highly integrated thermal management system. For all product developments, the technology and systems engineering specialist for the automotive industry in development, supercharge air routing/cooling and high-voltage and thermal management systems assumes complete consulting, support and project responsibility, including monitoring the process technology. All with one goal in mind: more efficiency and speed in the process.

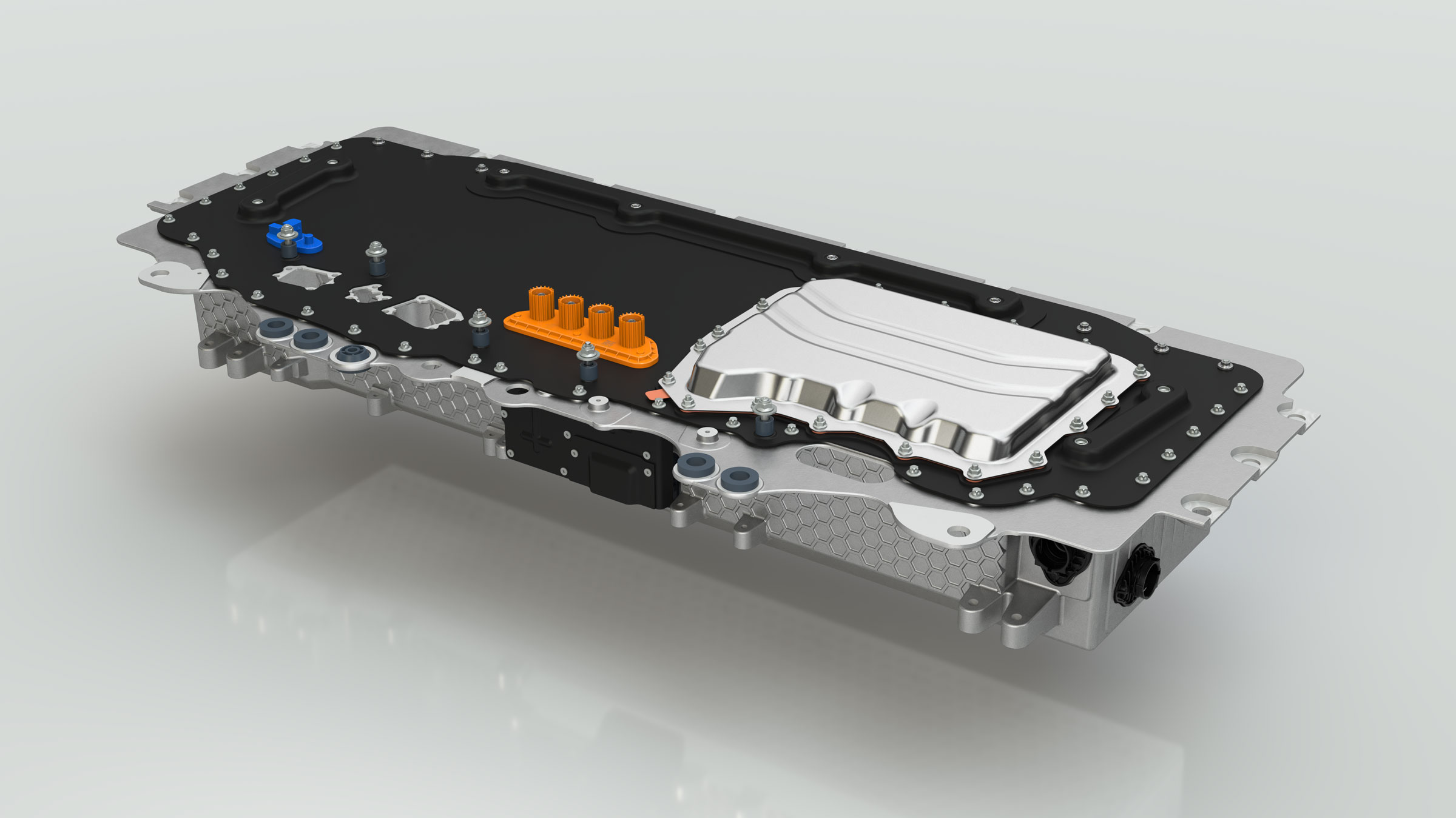

Established in 2003, the full-service provider Handtmann Systemtechnik is one of the fledgling divisions of the tradition-steeped group of companies. For nearly ten years, Handtmann Systemtechnik has been developing a wide variety of electric mobility concepts for leading automotive manufacturers. The newly developed hybrid battery from Handtmann impresses with an output of around 300 kilowatts at 800 volts. The energy is supplied by 21700 format lithium-ion high power cells. “At the Battery Show, we will, for the first time, be presenting the prototype of the new hybrid storage system, which we designed completely in-house, from the initial idea to the thermal and electrical performance analysis,” comments system developer Christopher Zell. The first hybrid storage systems will soon be used by one of Germany’s leading automotive manufacturers.

State-of-the-art battery test stand in operation at the headquarters since mid-May

In mid-May, Handtmann put a state-of-the-art battery test stand into operation at the company headquarters in Biberach an der Riss for the testing of prototypes during development, such as the new hybrid storage system or design types. “On the 130 m2 test field and in the 16 m3 test chamber, we can optimally analyse all thermal and electrical performances for systems with a rated output of up to 1.1 megawatts and adapt them to customer requirements”, explains Zell. Handtmann Systemtechnik is thus in a position to meet and advance the performance and test requirements of the next generation of batteries at all times. Furthermore, the test bench is in line with the latest state of the art for cooling systems as it can also be used to test systems with immersion cooling.

Battery modules adapt to installation space and performance requirements

Handtmann Systemtechnik solves the individual storage challenges of its customers from development to high-volume production – with speed, a focus on service and many years of practical experience. The high-voltage battery systems have a capacity of 20 to 100 kilowatt-hours and can be interconnected to form a unit or battery set with several mega-watt hours. With voltage options up to 1,000 V DC, Handtmann battery modules can be individually adapted to the customer’s installation space and performance requirements. In this way, the full-service provider guarantees reliable operation and a long service life with maximum flexibility.

ITS thermal management module is significantly lighter and more efficient

The ITS thermal management system for battery-powered electric vehicles increases system efficiency while offering uncompromising performance and service life. With a heating capacity of 7 to 14 kilowatts and a cooling capacity of 7 to 18 kilowatts, the unit ensures the optimum functionality of the water-cooled battery packs, even under extremely hot or cold ambient conditions, thus extending their service life. As the central interface between coolant and refrigerant, the ITS from Handtmann covers all operating scenarios both while driving and stationary. The heart of the system is a rotary valve. The unit is supplemented by electric coolant pumps and the optional coolant expansion tank. The evaporator with expansion valve, heat exchanger and storage tank form the interface to the refrigerant circuit. “Thanks to the variable installation options and compact design, we can flexibly integrate the ITS into a wide variety of vehicles. We have also reduced the number of components and interfaces as well as the volume of refrigerant and coolant. This makes the ITS significantly lighter and more efficient”, says Marcel Steinbach, Head of Product Development at Handtmann.

Further information:

Handtmann Systemtechnik GmbH & Co. KG

Markus Michelberger

Business Development Manager

Arthur-Handtmann-Str. 7/1

88400 Biberach/Riss

Telephone +49 7351 342-7712

markus.michelberger@handtmann.de

www.handtmann.de

Press and public relations:

Press’n’Relations GmbH

Nina von Imhoff / Uwe Taeger

Magirusstraße 33

89077 Ulm

Telephone: +49 30 577 00-326

Fax: +49 731 9628797

nvi@press-n-relations.de

ut@press-n-relations.de

www.press-n-relations.de